Building Blocks of a Pallet

21 Jul 2017

The pallet has been described as the most important unit of domestic and international commerce, as it facilitates the efficient transportation of goods across the planet. Despite their significance and ubiquitousness, though, most of us seldom have neither the time nor inclination to examine them and understand their structure. In fact, when we see pallets for sale, we might assume that they are of universal design. They are actually much more varied.

Materials

Wood – either soft or hard – is the most popular material for pallet manufacture, because it offers advantages such as being inexpensive, light, stiff, durable and easily modified for custom design. Equally, it can be repaired and recycled, making it environmentally friendly.

Plastic is also a common choice for those who want to buy pallets, essentially owing to its longevity. Other materials used include metals, wood composite and even paper, and each of these has its advantages. Wood and plastic, however, remain the overwhelming commercial favourites.

Dimensions

There is no international standard for the height, depth and width of an individual pallet, and they vary significantly from country to country. To complicate matters further, there are custom models on the market. The following, though, are the six common dimensions (width by length in millimetres):

Europe and Asia – 1000 x 1200; Europe – 800 x 1200; USA – 1219 x 1016; Australia – 1165 x 1165; North America and Asia – 1068 x 1067; Asia – 1100 x 1100.

The most frequently found heights are: 80, 110 and 220 centimetres.

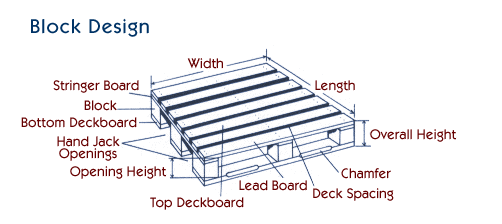

Main Components

The top surface of the pallet on to which goods are placed comprises top deckboards, and their length forms the width of the pallet. These top deckboards sit on stringer boards, which are at right angles to them. There will typically be three stringers on a wooden pallet, and it is the length of these stringer boards which defines the length of the pallet. The gaps between each deckboard are known as the deck spacing.

The bottom of the pallet consists of bottom deckboards, of which there will usually be three running in the same direction as the deckboards. The bottom deckboards are separated from the stringers by blocks. There is one block at each end of the bottom deckboard and an additional one in the centre.

The gap between the top and bottom deckboards defines the opening height of the pallet, and it is into this space which the prongs of a forklift truck are inserted. To facilitate this, the bottom deckboards have a chamfer on the edge to ensure that the wheels on the prongs don’t snag when being inserted. The other two sides of the pallet are usually open, as there is no bottom deckboard. The gaps between the stringers and the floor are known as hand jack openings and are used when moving the pallet around the warehouse or yard rather than for lifting and stacking.

The overall height of the pallet is defined by the combined thicknesses of the top and bottom deckboards, stringer boards and height of the blocks. This determines how many units can be stacked for storage.

If you wish to buy wooden pallets, why not check out our website for more information?