Pallet Terminology Explained!

19 May 2014

A pallet may look like a simple construction that supports goods, but anyone who tries to order one soon realises that pallet design consists of many factors and has its own terminology. As with any other industry, the pallet business is full of its own jargon which is often incomprehensible to outsiders.

In general, wooden pallets for sale may be described according to the final product, its components and the materials used to put the whole together and various testing procedures to ensure pallet quality.

Product Descriptions

- Box or bulk container pallet. These are pallets with solid or board sides. Some may be hinged or removable for access.

- Euro pallet. The standard size of a pallet used in Europe, which is 1200 mm by 800 mm.

- Four-way pallet. A pallet designed for pick-up from any of its four sides.

- Free entry pallet. This is a flat pallet with spaces along its sides that allow the forks of a fork lift truck to pass through.

- Injection-moulded pallet. The commonest type of plastic pallet that is formed from molten thermoplastic cooling within a mould.

- Nestable pallet. These pallets have apertures at the top into which the feet of another pallet will fit and allow stacking when the pallets are empty.

- Skid. A pallet that does not have a bottom deck. Also known as the single face pallet.

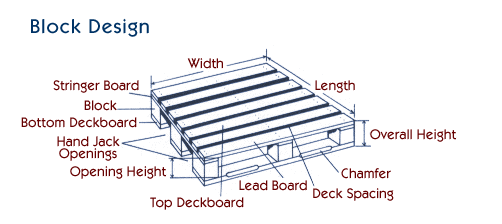

Components

- Batten. A reinforcement on a wooden deck to provide more rigidity.

- Chamfer. Deck boards with one or more bevelled edges. This may be along the entire length of the boards or between stringers. The idea is to ease the entry of forklift truck prongs or pallet jack wheels.

- Deck. An assembly of boards that make up the top or bottom surface of the pallet.

- Deckboard. One of the boards that make up the deck. These are oriented at right angles to the stringers.

- Stringer. This is a continuous component placed between the top and bottom decks of a pallet and provides the space for the entry of fork lift truck prongs.

Materials

- Nails. Pallets are assembled using steel spiral nails varying in length between 1.5 and 3.0 inches. They could be heat-treated or resin-coated to increase their vertical and lateral resistance.

- Nail points. The nails commonly have a diamond point that minimises breakage in the wooden materials. A chisel point on a nails reduces the risk of the plank splitting and is often used for hardwood. A blunt point eliminates any possibility of the plank splitting and is used for hardwood pallets.

- Soft nail. This is a nail with a Mibant angle (see below) equal to or greater than 47 degrees.

- Hard nail or hardened steel nail. A heat-treated pallet nail made of steel and with a Mibant angle between 8 and 28 degrees.

Tests

- Mibant test. The Morgan Impact Bend Angle Nails Tester is a method of testing the resistance of a nail to bending. An impact hammer of fixed weight strikes a nail that is held in a vice. The angle at which the nail bends to the hammer force — the Mibant angle — is measured.

- Unit load. The total weight of goods assembled on a pallet and measured as a single entity.