ISPM 15: The Ultimate Guide (2020)

Introduction

This is the regulation that requires heat treatment for wooden pallets, also known as pest control. It applies to transport between the EU and the rest of the world. ISPM15 regulations apply to all pallet wood, wooden collars and boxes. As of 1st January, we will have to meet ISPM 15 international standard for every pallet going in and from the U.K., as we will be classed as a third party country.

When it comes to shipping there is perhaps no item more important than the humble wooden pallet. It facilitates the shipment of millions of items every day. However it can also be a hotbed of pests, contaminants and disease if not treated. So to avoid the risk of spreading pests and diseases around the world the ISPM 15 was created.

We dig deep and look at all the aspects of ISPM 15 and what it means for wooden pallets! Read on to learn all about ISPM 15.

Contents

Chapter 1: What does ISPM 15 stand for and what does it mean?

Chapter 2: What does ISPM 15 describe?

Chapter 3: What countries require ISPM 15?

Chapter 4: Why do wooden pallets need to be heat treated?

Chapter 5: How do you heat treat a wooden pallet?

Chapter 6: Can heat treated pallets be reused?

Chapter 7: What markings do heat treated pallets have?

Chapter 8: Frequently Asked Questions

Chapter 9: How to recognise wood infestation

Chapter 10: Heat treated pallet inspection and mark removal process

Chapter 11: Benefits of heat treated pallets

Chapter 12: Updates to ISPM 15

Chapter 13: Conclusion

Chapter 1: What does ISPM15 stand for & What Does It Mean?

ISPM 15.

It sounds important right? But what actually does ISPM 15 stand for and what does it mean? ISPM 15 stands for International Standards For Phytosanitary Measures No. 15.

Let’s break it down a bit more and shed some light on the matter. International standards are guidelines developed by an organisation for use around the globe. The most prominent organisation that develops international standards is the International Organisation for Standardisation more commonly referred to as the ISO.

Phytosanitary measures are measures that are taken to help protect humans, animals and plants from contaminates, pests or diseases.

Quite simply ISPM 15 or International Standard for Phytosanitary Measure 15 is the 15th measure to protect humans, animals and plants from disease, pests and contaminants.

Now we know what the name actually means, we’ll dig into what this particular measure actually describes.

Chapter 2: What does it describe?

ISPM 15 is one of 24 International Standards for Phytosanitary Measures. Or to give it it’s full name: International Standards For Phytosanitary Measures Ispm No. 15 Guidelines For Regulating Wood Packaging Material In International Trade (2002).

We’ll breakdown what ISPM 15 covers in easy to digest chunks. Essentially as the name would suggest ISPM 15 is all to do with wood packaging in international trade. As you’re likely aware millions of wooden pallets are shipped to and from different countries every day to facilitate the transport and logistics of goods. With pallets being constructed from wood this obviously has a huge risk of spreading pests, diseases and contaminants in the wood.

That’s where ISPM 15 comes in.

Its sole purpose is to reduce the risk of introducing and/or spreading pests, diseases and contaminants associated with wood packaging material used in international trade. Specifically, wood packaging (and dunnage) made of coniferous and non-coniferous raw wood. However,it excludes any wood packaging processed in such a way that makes it free from pests, such as plywood.

ISPM 15 describes a standard that is not intended to provide ongoing protection from contaminating pests or organisms. It describes three approaches to eradicating the potential for pests and contaminants.

These are:

- Heat Treatment

- Kiln Drying

- Methyl bromide (MB) fumigation for wood packaging material

There are strict regulations for each of these approaches which ensures that pests, diseases and contaminants are all eradicated.

Chapter 3: What countries require ISPM15?

Wooden pallets used in freight to and from Europe are required to be heat-treated to ISPM 15 standard. As we are leaving the EU, we will no longer be categorised here and will be known as a third-party country.

The Government’s guidelines state:

“All WPM moving between the UK and the EU must meet ISPM15 international standards by undergoing heat treatment and marking if there’s a no-deal Brexit. All WPM may be subject to official checks either upon or after entry to the EU. Checks on WPM will continue to be carried out in the UK on a risk-targeted basis only. The plant health risk from WPM imported from the EU is not expected to change as a result of Brexit.”

ISPM 15 applies to international trade so its important that countries adhere to this measure to stop the spread of pests.

Here is a comprehensive list of different countries who require wooden packaging entering their country to meet ISPM 15 regulations.

- Argentina

- Australia

- Bangladesh

- Bolivia

- Brazil

- Canada

- Chile

- China

- Colombia

- Costa Rica

- Cuba

- Dominican Republic

- Ecuador

- Egypt

- EU

- EU (Portugal)

- Guatemala

- Guyana

- Honduras

- Hong Kong

- India

- Indonesia

- Israel

- Jamaica

- Japan

- Jordan

- Lebanon

- Malaysia

- Mexico

- New Zealand

- Nicaragua

- Nigeria

- Norway

- Oman

- Paraguay

- Peru

- Philippines

- Republic of Korea

(South Korea) - Russia

- Seychelles

- South Africa

- Sri LankaSwitzerland

- Syria

- Taiwan (includes Taipei),

- Penghu, Kinmen and Matsu

- Turkey

- Ukraine

- USA and North America

Here is a thorough list of how each country implements ISPM 15.

Chapter 4: Why do wooden pallets need to be heat treated?

We’ve established that one of the main approaches to becoming ISPM 15 compliant is through heat treatment. Heat treatment is one of the few officially approved approaches which meets ISPM 15.

This is because heat treatment successfully eliminates all of the following pests.

- Insects

- Anobiidae

- Bostrichidae

- Buprestidae

- Cerambycidae

- Curculionidae

- Isoptera

- Lyctidae (with some exceptions for HT)

- Oedemeridae

- Scolytidae

- Siricidae

Nematodes

- Bursaphelenchus xylophilus

This illustrates the effectiveness of heat treatment in eradicating harmful insects from wood packaging materials. Stopping them from being transported around the globe. In fact, there are other treatments such as Kiln-drying (KD), chemical pressure impregnation which can be considered heat treatment as they meet the requirements through the use of steam, hot water, or dry heat.

Furthermore, heat treatment is actually considered the best treatment type for ISPM 15. Other treatments such as chemical fumigation have actually resulted in recalls in the food and pharmaceutical industries due to traces of chemicals being found. Chemical fumigation can also leave an unpleasant smell which isn’t desirable. This is another reason why heat treatment is so important and considered the best and safest way of adhering to ISPM 15. Heat treatment for ISPM 15 eradicates insects and larvae, reduces moisture content and makes it safe to handle pallets.

Chapter 5: How do you heat treat a wooden pallet?

Wood packaging material such as wooden pallets should be heat treated using a specialist kiln in accordance with specific guidelines which lay out temperature and duration. Wood packaging should be heated till the minimum wood core temperature reaches 56 degrees celsius. This core wood temperature should be maintained for at least 30 minutes.

It’s been documented that a temperature of 56 degrees celsius is required to eradicate a wide range of pests but is also still commercially feasible. Someone pests have actually been known to have a tolerance to higher temperatures, however pests in this category are managed by NPPOs on a case by case basis. In fact, some countries actually do require that a higher core temperature to be maintained to adhere to ISPM 15.

Wood packaging such as wooden pallets are heat treated by being placed in a specialised plant or kiln which heats the wood to a specific temperature which is then maintained. Kilns or plants may be subject to inspections to make sure they’re adequate for the job in question.

Chapter 6: Can heat treated pallets be reused?

If you wish to reuse pallets, either for transportation or a fun weekend project you need to be careful. Pallets and wood material can be treated using harmful chemicals you will want to make sure that it’s safe to reuse your pallet. Thankfully pallets which have been heat treated are safe to reuse. As all this means is that they’ve been heated to a specific temperature for a certain time period to kill insects and larvae.

Whereas other treatments such as Methyl bromide can be harmful and should be avoided for weekend projects. Once a pallet has been heat treated to ISPM 15 standards companies and organisation can confidently use it to ship and transport well globally.

ISPM 15 will last the lifetime of the pallet. So once it has been heat treated it can be used throughout the entire lifetime of the pallet and will not require re-treatment. This may change if the pallet goes through any kind of repair or remanufacture work.

Chapter 7: What markings do heat treated pallets have?

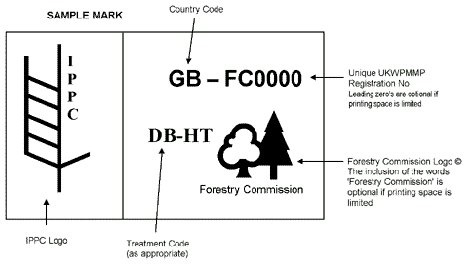

Obviously, the pallets have to be stamped to show that they have been through this process. Pallets that have been through the ISPM 15 process will be stamped with an authentication mark that is recognised worldwide. This consists of the IPPC logo, which is an ear of corn with the “IPPC” mark next to it. Then there’s the two-letter International Standards Organisation country code. So for pallets from the US, this would be US; for pallets from Great Britain, it would be GB.

It’s very important that the wood packaging can be traced back and a chain of responsibility established for its whole passage into the supply chain. So the next part of the code identifies the regulator in charge of the process and the certification number used by the manufacturer of the pallet or the organisation that treated it.

Then there are two more letters that tell you how this pallet has been treated. If it’s had a compliant heat treatment, it will bear the letters HT. If it has been fumigated using the chemical methyl bromide, it will be stamped with the letters MB. These are the absolute essentials for the stamp to show that it is compliant.

However, some pallet manufacturers choose to add extra details on their heat treated pallets. But if you see the ISPM 15 authentication mark, you know that the pallets are safe to use.

ISPM 15 Mark Regulations & Fraud

ISPM15 is the industry standard regarding wooden pallets. The regulations state that all wooden pallets must be heat-treated prior to use and have an ISPM15 mark to show they comply. This proves that the wood has been heat-treated appropriately and is free of pest infestations. The process can be costly, and this has led to some suppliers carrying out fraudulent practices, including the use of marks on untreated products.

Failure to Comply

A recent case in the US was brought against a pallet company for mark fraud. The company involved, and its former owner, pleaded guilty to the charges and were fined $100,000 for knowingly using ISPM15 stamps on pallets that hadn’t been treated properly. This is the largest fine that has been handed down under the Plant Protection Act with regards to wooden pallets.

The company involved placed stamps on wooden pallets to indicate that they complied with ISPM15 regulations when in fact they didn’t. The wooden pallets were then used to transport goods overseas from the US, contravening the regulations. They were also sold to a number of other companies that believed that they were purchasing legitimate pallets.

The action was brought against the company by the US Department of Agriculture (USDA) and the US Department of Justice (DOJ). The company and owner were charged with crimes relating to the use of false certificate stamps. Both of these organisations are working together to take action against suppliers who contravene the Plant Protection Act. The USDA is the National Plant Protection Organisation of the US and has put together an export programme that guarantees compliance with any of the import requirements of other countries.

Ensuring Compliance

When you’re purchasing wooden pallets, you want to be sure that the products you’re getting have been heat-treated correctly and are safe to use. At Associated Pallets we have our own kiln on-site. This enables us to monitor the heat-treatment of pallets and ensure that the process is carried out in the correct manner. It means we can guarantee our customers that the wooden pallets we supply are fit for purpose and comply with ISPM15 regulations. As part of this process, we supply all our pallet customers with a certificate to prove heat-treatment, along with a graph that shows the process of treatment the pallet has undergone.

When you’re purchasing wooden pallets, it is vital that you check if they have been treated appropriately. They must carry the correct mark, and you can ask your supplier to provide a certificate to guarantee this.

The ISPM15 regulations are an important aspect of the wooden pallet industry. With the increase in global trade, this is a vital element that eliminates the risk of pest infestations and ensures that all wooden pallets are fit for purpose. It’s important that any companies found to be flouting these rules are dealt with accordingly, as this sends out a clear message to other suppliers that it’s not worth trying to get round the law.

Chapter 8: Frequently Asked Questions

Can you burn wooden pallets?

Generally wooden pallets are safe to burn however you must take extra care when doing so.

If your pallet has the symbol MB printed on it do NOT burn it. This is a sign that the pallet has been treated with Methyl Bromide which can be harmful and should not be burned.

So long as your pallet hasn’t been treated with any harmful chemicals it should be safe to burn. Just watch out for nails when breaking it up.

Typically wooden pallets burn with a hot flame as they’re normally very dry and thin.

Is processed wood exempt from ISPM 15?

Wood packaging made out of processed woods such as plywood, particle boards and oriented strand boards are considered ISPM 15 exempt.

The process of producing these types of wood means there is a low risk of harbouring pests or contaminants.

What does a blue pallet mean?

Blue pallets typically identify wooden pallets which are part of the CHEP (Commonwealth Handling Equipment Pool).

Who controls ISPM 15?

ISPM 15 is controlled by the International Plant Protection Convention (IPPC) as a part of the United Nations Food & Agriculture Organisations (FAO). They control the regulations through cooperation of UN member governments.

Chapter 9 – How To Recognise Wood Infestation

Also called the starry sky or the sky beetle, the Asian longhorn beetle is a species native to China, Korea and Japan. Over the last 20 years, this beetle has been spreading to North America and Europe, mostly through wood packaging material.

Today, this beetle probably poses the greatest threat to date to traditional British and European broad-leaf trees. It was first discovered in Britain in 2012. The Food and Environmental Research Agency and the Forestry Commission are working together to find a way of eradicating it.

The presence of the Asian longhorn beetle can be recognised by piles of sawdust at the base of trees, scraped bark, bleeding sap and exit holes in the tree’s main trunk together with feeding damage caused in the bark of branches and shoots.

The Pine Wood Nematode is a native species of the Unites States but also occurs in China, Japan and Portugal. This insect causes wilting in pines and was first recognised in the early 1900s in Japan.

These pests will infest any wood packaging material that is made from raw and untreated timber. In addition, old wood packaging material is frequently repaired and re-used so the infested material may spread the insects over a large geographical area.

Chapter 10 – Heat Treated Pallet Inspection and Mark Removal Process in the US

The issue of pallet hygiene is a well documented one. Pallets are inspected – especially when they are heat treated – and then marked to show they meet the required standards.

At Associated Pallets, we heat treat our wooden pallets to ensure they meet the required ISPM15 standard that governs pallet hygiene and health. Heat treating pallets in this way not only improves the quality of shipments, but also offers pallet-users peace of mind. Pallets which have been appropriately treated are then marked accordingly, and users from then on can rest easy in the knowledge that their pallets are safe to use. This works much in the way that EPAL mark pallets which have been constructed to their standards.

However, problems can arise when pallets age or move across borders. Although ISPM15 is an internationally recognised standard, when pallets’ usage changes or requirements change, these standards can cause problems.

In the US, this marking process has been causing a previously unforeseen problem. Domestically repaired pallets must be heat treated and re-certified with the ISPM15 mark removed, but sometimes these can be missed.

If a stamp is missed and is found by an inspector, that entire group of pallets can be put into quarantine. This can have devastating logistical impact. This was unfair on organisations who were innocently missing ISPM15 marks that should have been removed but were still meeting the US’ heat treated pallet regulations.

The end result was an agreement that the level of pallets with marks removed had to be over 5% for a quarantine to be implemented.

The ALSC and the NWPCA are working together (American Lumber Standard Committee and National Wooden Pallet & Container Association) to outline and define clear and fair standards for when marks need to be removed. This includes changes to the quarantine process.

Chapter 11 – The Benefits of Heat Treated Pallets

When you’re choosing a pallet manufactured from wood, it’s vital that you understand the benefits of using heat treated pallets. Heat treatment is essential in order to comply with ISPM15 requirements, which prevent the transfer of pesticides and infestation during the exportation process. However, there are also other advantages to using wooden pallets that have been heattreated, including enhanced sterilisation, durability and weather resistance. At Associated Pallets, we can supply heat treated pallets, and we also offer heat treatment services for your wooden packaging.

How Are Pallets Heat-Treated?

In order for the heat treatment process to be efficient, it needs to be carried out correctly. The timber that is being used must first be debarked, as just the core is required for pallet production. The wood must then reach a temperature of at least 56 C or 132.8 F. Heating the wood to this temperature will remove a large amount of the moisture, which would otherwise result in the pallet rotting. The heattreatment process also increases the weather resistance of the pallet. When the pallet has been correctly treated and dried, it will be marked with the ISPM stamp as well as the country of origin.

Benefits of Heat Treatment

The International Phytosanitary Standard for Wood Packaging, otherwise known as ISPM15, requires that all wooden forms of packaging, including pallets, are heattreated before they’re used for shipping. The standard has been adopted by all the members of the European Union and 14 other countries globally, but it does not apply to plastic pallets. The main reason for this requirement is to minimise the risk of infestation. The spread of insects and other pests from overseas can have a significant impact on the local environment. Insect contamination can even result in illnesses for those who handle the pallets. Increasing sterilisation levels is another benefit of heat treating wooden pallets. Plastic pallets are easier to clean thoroughly between uses than wooden ones are. A wood pallet is at increased risk of developing bacteria and mould, especially if it is not stored correctly, due to the levels of moisture in it. However, pallets that have been heattreated will have had some of this removed, decreasing the risk of bacteria and mould developing.

Purchasing Heat-Treated Pallets

At Associated Pallets we can make it easy for you to stay within the ISPM15 guidelines. We can supply a range of heattreated wooden packaging, including pallets, crates and pallet collars. All our packaging products come with a certificate to prove they have been heattreated correctly, company registration document and details of the process, so you can have peace of mind about your purchase. We also offer heattreatment services for any size of shipment to ensure that all your packaging meets the necessary standards.

Chapter 12 – Updates to ISPM 15

Pallets made of wood, metal or plastic are used to ship goods both nationally and internationally. In order to be used for international trade and shipping, however, wooden pallets need to be treated. The International Standards for Phytosanitary Measures 15 (known as ISPM15) sets out guidelines for the treatment of wooden pallets.

Until very recently, wooden pallets had to be either heat treated in an enclosed chamber or fumigated with methyl bromide. Then the pallets were marked to show that they complied with the international standards. Now, in addition to these treatments, ISPM15 has been updated to include dielectric heat treatment.

What Is Dielectric Heat Treatment?

Dielectric heat treatment involves using microwaves to bring the wooden packages to a minimum of 60 degrees Centigrade. This temperature needs to be reached within 30 minutes of the beginning of the process, and it must be achieved across the whole profile of the wood. Any manufacturer that wants to offer this treatment for ISPM15 pallets must be approved by the NPPO (National Plant Protection Organization).

What Are the Benefits of This Type of Heat Treatment?

One of the most obvious benefits of this method of producing heat treated wooden pallets is time. It takes much less time to treat pallets in this way, and it also requires fewer operators. In this way, it can be a very cost-effective method of heat treatment.

Dielectric heat treatment equipment also takes up considerably less space than conventional heat treatment chambers. This means that more equipment can be fitted into heat-treating premises and manufacturers can produce more heat treated pallets. There is also less handling required of the wooden pallets, so there is less likelihood of damage during the process. This means that manufacturers have access to a process which is quicker, requires less space and fewer operators and produces less damage than conventional heat chamber treatment.

What Are the Drawbacks?

The main drawback of the dielectric heat treatment process is the initial cost of the equipment, which is higher than that of a heat treatment chamber. Changing over from a chamber to dielectric could be expensive for some manufacturers, especially if their chamber is relatively new. Running costs and maintenance could also be more expensive, although as the process is so new there is relatively little information about reliability or energy consumption over time. If these costs turn out to be high, then they will be passed on to consumers, and this could make the pallets too expensive for many buyers.

Dielectric heat treatment of wooden pallets is an efficient and modern process which will help prevent the spread of dangerous pests and diseases. As more manufacturers turn to this process, it will become less costly, and it will be easier to compare to conventional heat or fumigation treatments of ISPM15 pallets to the new dielectric treatments.

Chapter 13: Conclusion

So there we have it.

Everything you could possibly want to know about ISPM 15.

We now know exactly what it is and why it exists.

We’ve discussed the heat treatment process as well as different markings and what they mean.

We even identified some of the different pests we’re trying to eliminate through heat treatment!

Finally, we finished up with some frequently asked questions!

However, be sure to check back later as we’ll continue to expand and improve this ultimate guide to ISPM 15.

Thanks for reading 🙂