The Ultimate Guide To Choosing The Right Wooden Pallet For Your Specific Needs

Learn which wooden pallets will meet your needs

Ensuring you select the correct pallets for your needs is of vital business importance. This can help you maximise and protect shipments, making sure they arrive at their intended destination whilst not costing you the world.

There are so many different pallets available it’s sometimes hard to know which one you should order for your business.

Do you need a heat treated pallet for instance? Or should you buy UK or Euro standard sizes? Maybe you’re unsure if you should buy new or used?

Whatever your requirements then the following will help shed some light on the nuances and complexities of the pallet world and help you make an informed decision for your next pallet purchase.

Short on time?Look at this flow chart to make a quick decision. |

Contents

Your Complete Guide To Purchasing Pallets

This guide will give you everything you need to make an informed decision when ordering your first or next pallet order. From types, construction materials, load capacities to heat treatment and pallet accessories.

Chapter 1: What is a Wooden Pallet?

How understanding pallet construction materials can save you money

Chapter 2: Types of Pallet

How to pick the right type of pallet to improve your shipping abilities

Chapter 3: Pallet Sizes

How to picking the right size pallet can save you money on shipping costs

Chapter 4: ISPM / Heat Treated Pallets

Don’t fall foul of hygiene shipping laws, make sure you understand the implications of ISPM 15

Chapter 5: Pallet Options

How different pallet sources can affect your budgets

Chapter 6: Pallet Accessories

How to protect your shipment with these pallet accessories

Chapter 7: Pick Your Pallet Flow Chart

How to quickly select the best pallet for your needs

Chapter 8: The Life Cycle Of A Wooden Pallet

Chapter 1: What is a Wooden Pallet?

understanding pallet construction materials

Introduction

To be in a position to make an informed and business orientated decision about your next pallet order it’s important to understand the fundamentals of pallets including wood types and construction methods.

These factors will ultimately play a part in deciding which pallets actually suit your business requirements.

What are pallets made of?

Whilst there are hundreds of types of wood used in the construction of wooden pallets all can be categorised into two groups:

Hardwood and softwood.

Hardwoods such as mahogany, maple, oak, teak and walnut are classic examples of ancient woods often used in former times to make furniture.

However, softwoods such as pine, Douglas fir, spruce and yew are used in many more applications, with pine being the most widely-grown and used wood today and often utilised in wooden pallets.

While pallets can be made from a variety of different woods, their composition often depends on their country of origin. This is because pallets are an example of just one part of a much larger supply system.

Pallet makers are looking for a wood that is not only fit for purpose but also readily available. When a wood supply is high and readily available, the supply chain to make the pallets is consistent and – most importantly – the price of the raw product is cheap.

Pine is frequently used in pallets because it is a clean product that can be kiln dried without causing any damage. This makes it suitable for shipping and storing food products and pharmaceuticals. Oak is a considerably stronger material; however, to farm and fell oak just for pallets would obviously be expensive.

As oak is used in a range of other products, off cuts unsuitable for furniture are sometimes available. As oak is stronger than pine, thinner boards can be cut to achieve the same level of strength.

As a rule, softwoods are cheaper because they grow faster and are more readily available. They are also easier to cut and prepare. Hardwoods are often more expensive, as they take much longer to grow and may grow in areas that are less easily managed.

If money were no object most customers would opt for hardwood due to its increased strength, however in the real world, softwood such as pine is normally the appropriate choice.

How are they made?

The beauty of wooden pallets is the way they are constructed to produce a structure which is capable of facilitating the movement of goods domestically and internationally.

The top surface of the pallet on to which goods are placed comprises top deckboards, and their length forms the width of the pallet.

These top deckboards sit on stringer boards, which are at right angles to them.

There will typically be three stringers on a wooden pallet, and it is the length of these stringer boards which defines the length of the pallet.

The gaps between each deckboard are known as the deck spacing.

Chapter 2: Types of Pallet

How to pick the right type of pallet

Introduction

Though there are many different types of wooden pallets that come in many different sizes and configurations there are two main broad categories that all pallets inevitably fall into:

Stringer pallets and block pallets.

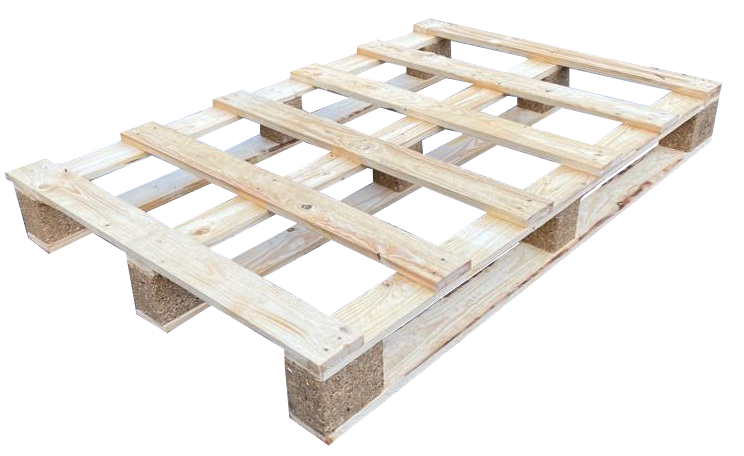

Stringer Pallets (aka Two Way Pallets)

The so called stringer pallet design is named after the three or more parallel pieces of timber (called stringers) that make up the frame.

The top deckboards are then attached to these parallel stringers to create the familiar wooden pallet structure.

There are two common configurations of the stringer pallet design, which reference the number of forklift entry options available:

The two-way stringer pallet and the four-way stringer pallet.

The two-way is the default of all stringer pallets however a notch can be cut into them converting them into a four-way which allows forklift entry from four sides.

A stringer four-way is not to be confused with a block pallet which can also be known as a four-way pallet.

Another factor to be aware of is that two-way or stringer pallets are designed to be lifted by their deckboards.

Block Pallets (aka Four Way Pallets)

The other major wooden pallet design are known as block pallets.

Block pallets are normally stronger than their stringer alternative.

They are constructed using both parallel and perpendicular stringers to better facilitate handling. Quite often a block pallet will also be known as a four-way pallet.

Due to the additional stringer boards more timber is required in construction which makes them more durable but for a greater cost than the two way alternative.

In contrast to two-way pallets, four way pallets are designed to be lifted by their more rigid stringers instead of the deckboards. This is advised they are usually bigger and heavier than their two-way cousins.

Chapter 3: Pallet Sizes and Load Capacities

picking the right size pallet

Introduction

As with all things pallet, there are many different options available to you:

And when it comes to pallet size it is no different.

It’s important that pallets can easily pass through buildings, stack and fit in racks and be accessible to forklifts and pallet jacks.

This has led to the development of an array of different standard sizes that are widely used throughout the world.

When looking at pallet dimensions, the first number is the stringer length and the second is the deckboard length. Understanding this will help you make the right pallet selection.

UK Standard Sizes

The UK has its own set of standards.

The sizes vary according to the height, width and length but also according to how much the pallet itself weighs and how much can be loaded on it.

Some, but not all, of these pallet sizes will be acceptable in a number of European countries.

The standard UK pallet is generally accepted as being 1000mm x 1200mm.

A pallet weighing 14kg would be able to take approximately 500kg of load, depending on what it is made of.

Euro Standard

Across Europe, including the UK, the most widely used pallets are Euro pallets.

Euro pallet size is commonly 1200mm x 800mm with a height of 150mm, although other sizes are available.

Euro pallet production is very closely regulated by the European Pallet Association (EPAL), so the pallets are also produced to standard specifications for different applications and industries.

Here is a breakdown of the common Euro pallet standards:

- EUR, EUR 1 – 800 mm × 1,200 mm × 145 mm

- EUR 2 – 1,200 mm × 1,000 mm × 144 mm

- EUR 3 – 1,000 mm × 1,200 mm × 144 mm

- EUR 6 – 800 mm × 600 mm × 144 mm

ISO Standards

The International Standards Organisation has tried to rationalise the system by bringing in its own set of standards. The result has been that these standards sit alongside the Euro pallet dimensions and other sizing standards, so a common global approach hasn’t been achieved. However, ISO has defined six pallet measurements for sending goods between continents.

These are:

- 800 × 1200 mm for use in Europe

- 1000 × 1200 mm for use in Europe, Asia

- 1067 × 1067 mm for use in North America, Europe, Asia

- 1100 × 1100 mm for use in Asia

- 1165 × 1165 mm for use in Australia

- 1219 × 1016 mm for use in North America

Which size you should use means considering what you want to transport and where it’s going.

You also need to consider the type and size of forklift that your customer or warehouse may be using.

Finally, some industries need special types and sizes of pallet too so it’s important to take this into account as well.

CP

CP pallets are not a popular size, although frequently used in the construction, chemical and turfing industry.

Due to their strength and gap size between top boards, they make ideal pallets for bricks, blocks and oil drums.

Typical CP pallet dimensions include:

- 1140 x 1140 x 138

- 1150 x 1150 x 150

Others

In addition to these standards there are other pallets available with varying dimensions available.

Some of the other most popular standards are widely used in North America and include:

- 1016 × 1219 – used for groceries and many other industries

- 1067 ×1067 – used for telecommunications and paint

Load Capacities

In addition to ensuring you select the right size pallet it’s just as important (if not more important) to make sure you choose pallets which are cable of bearing the weight of the goods you wish to transport.

Pallet load capacity is the maximum amount of weight a pallet is designed to carry. The weight of the goods you wish to transport will have an effect on the types and sizes of pallets that are available to you.

For instance, if you have a very heavy load you will likely need a block pallet instead of a stringer pallet to cope with the greater forces involved.

Chapter 4: ISPM 15 / Heat Treated Pallets

understanding the implications of ISPM 15

Introduction

ISPM 15 is an international standard that is slowly but surely becoming an international requirement for phytosanitary measures.

While more than two dozen countries have already adopted the standard, a further twenty are currently implementing the changes, and another hundred have stated their intention to follow suit.

This includes many European Union countries as well as the United States, but the list is extensive and is continuing to grow. If you are in the industry and deal with products like heat treated pallets to transport your goods, you’ll want to know more about ISPM15 and what it means to you.

View our comprehensive list of ISPM 15 Country Guidelines here.

History of ISPM 15

ISPM15, or the International Standards for Phytosanitary Measures No. 15, has been developed by the IPPC (International Plant Protection Convention) with the aim of cutting down (if not cutting out) pests that are often associated with the movement of packaging material made from raw wood across international borders.

In essence, the standard has been designed to stop wood packaging being a means of transmission for pests that might end up causing harm to living trees.

Why is ISPM important

The international standard affects the cost of packaging due the extra work required in ensuring that it complies with it. This quest for compliance can also then lead to delays in shipping and potentially result in customer dissatisfaction, creating strained relationships between customer and manufacturer. Because the standard relates to packaging made from raw wood only, this implicates structures made from wood fastened together, like crates. As such, warehouse owners must educate themselves on the regulation.

Warehouse owners will be pleased to know that the regulations are not binding for heat treated wooden pallets or those that have been put through any other type of process involving heat, pressure, glue or similar methods. This means that materials like plywood, chipboard and fibreboard need not comply, but solid timber or pine crates do. The reason for this is that manufacturing processes carried out to treat the wood are effective enough in ensuring that harmful creatures and diseases have been destroyed and can’t be transmitted.

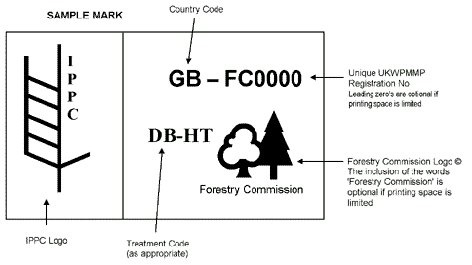

ISPM 15 Marking

To indicate compliance with ISPM 15, wooden products must display an identifiable mark.

There are three marks related to the standard: HT Mark, IPCC Mark and IMMC DUN (Dunnage) Mark.

The first is used on individual wood components and is itself made up of three elements, including an agency trademark, a facility number and the letters ‘HT’, all of which must be visible and legible.

This Mark does not replace the IPPC Mark – rather it links the site treating the raw product to the place that will certify completed WPM.

The IPPC Mark can be found on items like boxes and pallets. It includes the three elements of the HT Mark yet additionally includes a country code and the treaty’s wheat symbol twice.

Finally, the latter is found in wood packaging that is used for blocking or bracing. On top of the five aforementioned elements, this Mark requires the piece to bear the term ‘DUN’. This will be repeated if the dunnage is transported to another facility.

Chapter 5: Pallet Purchasing Options

How different pallet sources can affect your budgets

Introduction

When it comes to purchasing pallets, you have two main options:

New or used.

With both methods there are different advantages and disadvantages. Depending on your needs one avenue might be more beneficial than the other.

New Pallets

New pallets as the name suggests are obviously brand new pallets, often built to order to your required specifications.

Though, reasonable offers for new pallets can be found, they’re never going to be as cost effective as buying used.

However, if it’s important to you to have brand new pallets built to specific set of requirements, buy new may be the best option for you.

As new pallets have to be built, you may experience longer delays between ordering and receiving than if you purchased used which have already been produced.

Used Pallets

Used pallets are obviously pre-owned pallets which means you’re able to purchase at a much better price:

Some top suppliers will be able to offer them to you for around 60% of new pallets.

This is why they’re often the top choice for many customers.

Typically used pallets will have been refurbished and reconditioned to a high standard to make them very viable options for customers on a tighter a budget.

However, when buying used there are some important considerations to take into account to make sure you get top quality pallets.

Always examine what you are buying. Even those experienced in acquiring second hand pallets should investigate when going to a new supplier.

Pallets of the GMA variety should measure 48 inches by 40 inches, but they can be made of softwood or hardwood and be configured differently.

They may also have been repaired with plugs, companion stringers or steel plates.

Pallets can be classified according to quality:

While the grading may provide a reasonable idea of the condition of the pallets, don’t take the vendor’s word for it. Grades for premium pallets can include Club Grade or AAA for pallets that are almost new.

Grade A pallets tend to be in nearly new condition, with some change in colour and evidence of wear and possibly some stringer repair plates.

Grade B pallets typically allow some plates, along with a specified number of plugs and companion stringers.

However, not everyone grades pallets in the same way, so your own evaluation will always be more reliable than what someone else thinks.

Being very clear on the quality of the pallets and their defining features is essential.

Chapter 6: Pallet Accessories

How to protect your shipment with these pallet accessories

Introduction

In addition to picking the right pallets for your needs, you may also want to consider different accessories to help secure your shipment and protect your goods.

There are two major accessories to think about when it comes to wooden pallets:

Pallet collars and pallet wrap.

Pallet Collars

Pallet collars are a modern and efficient replacement for traditional wooden boxes. Constructed from four to six wooden boards with metallic hinges in each corner to hold the boards together.

The hinges allow the pallet collar to be collapsed when not in use. This has contributed to their growing popularity where such factors are very important in successful logistics operations.

These pallet collars are placed on top of traditional pallets to form box type storage.

The beauty of pallet collars is in their flexible construction which has allowed pallet collars to stand out from other alternative storage solutions. Their construction ensures that they can be adapted to suit different heights and sizes.

There are four standard manufacturing heights: 100mm, 200mm, 300mm, 400mm. These array of heights means it’s possible to closely match every single package to their contents.

There are also three standard sizes: 600×800, 800×1200 and 1000x1200mm. These will fit most common pallet sizes.

The most common material for pallet collars is softwood which provides the necessary quality, though other materials can sometimes be used.

Pallet Wrap

Wrapping a pallet correctly can be tricky to achieve, especially if you are doing it manually.

Wrapping a pallet correctly can be tricky to achieve, especially if you are doing it manually.

Here is a quick rundown of how to use pallet wrap, with advice that varies depending on the materials and tools that you have to hand.

Manual Wrapping:

If you have a roll of stretch wrap and you want to adopt a simple low-tech approach to wrapping, then you should start by tying wrap to the pallet itself to hold it in place and prevent unwanted movement.

Beginning at the lowest point, pull the new pallet wrap tight and begin to circle the pallet on foot, completing three circuits so that the base is strong, stable and unlikely to shift further down the line.

Once this setup has been completed, you can begin to wrap higher and higher up the load, making sure that the subsequent layers have a good level of overlap. Always remember to check the specifications when you buy wrap to ensure that it can cope with the type of load that it needs to secure.

After wrapping to the top of the pallet’s load, add an extra layer of film across the top to hold everything in place, and then repeat the first steps in reverse, wrapping downwards to the base with consistent overlapping for an optimal outcome.

When you cut the wrap having reached the bottom, make sure that it is fastened adequately to the load, which should be achievable by applying a little pressure.

Chapter 7: Pick Your Pallet

How to quickly select the best pallet for your needs

Introduction

Make your way through this flow chart to determine which wooden pallet you need.

Chapter 8: The Life Cycle of a Wooden Pallet

People have been using wood in packaging and for moving goods for hundreds of years, and that doesn’t look like changing any time soon. The lifecycle of a wooden pallet is relatively straightforward, though there is still room for improvement and reducing the impact of the process on the environment.

What Is a Pallet?

A pallet is a (generally) wooden structure that is designed to be moved and stacked by a forklift truck and to store and transport a huge variety of different products. It is a platform formation. Depending on the wood used, they are generally untreated and at 4″ by 4″ can hold a load of up to 1,000kg.

As consumers and businesses are taking a lot of interest in the sustainability of the goods they buy and what they are packed in, wood is in big demand. More durable wood can be reused several times, which reduces costs for the business and supports a more sustainable approach, and so the lifecycle of a wooden pallet becomes all the more interesting.

Seeding

A growing proportion of timber used in manufacturing now comes from managed sustainable woodland. Managing a forest is a complicated process, and encouraging the seedlings to grow can be challenging. Once they begin to photosynthesize, roots will start to grow properly and the seeds start to look like ‘real’ plants.

Many seedlings perish in the first year and don’t even make it to planting out, so someone running a managed forest will have to keep a careful eye on conditions: temperature, wind, light and water, for example. Young seedlings are also especially susceptible to disease and pests.

Logging and Milling

Those that do make it to fully grown trees will then undergo the process of logging and milling. Logging is the tree harvest, and then they are sawed into manageable lengths that are taken to the sawmill.

Construction of Pallets

Pallets are often categorised as ‘two-way’ or ‘four-way’, which refers to the number of sides a pallet can be lifted by a forklift, so a four-way has no restrictions. Of course, they can be made to any size, but there are some standard sizes and they are the lifeblood of many sectors’ logistics and supply chains.

Repair, Reuse, Recycle

Check your pallets for damage and general wear and tear regularly, just as you would with machinery in the warehouse. Depending on what you use the pallets for, you might want to check what, if anything, the wood in the pallet is treated with.

Once the pallet can no longer be used in a supply chain, there is a growing market for reusing wooden pallets, and people are using second-hand pallets for a whole host of domestic projects: coffee tables, beds, shelving and even decking can all give a pallet a new lease of life.

Keep up the basic maintenance and you’ll be able to prolong the lifecycle of a wooden pallet. The longer it lasts, the less the ultimate impact on the environment. Many consumers will buy second-hand pallets, and being able to make a small cash return must be a good thing for a business’s bottom line.